Artem Latyshev, SAP EWM MM Consultant, ACBaltica

Modern warehouses often rely on machines such as conveyors, sorters, and automatic elevators to move items quickly and accurately. But how do you know if they are working in sync with your warehouse software? This is where MFS (Material Flow System), a feature within SAP EWM, comes in. It serves as a bridge between your warehouse software and the machinery, helping everything run smoothly.

In this blog post, we'll explain what MFS is, how it works, when it’s needed, and what challenges to consider before implementing it.

What is SAP EWM MFS (Material Flow System) ?

SAP Extended Warehouse Management (EWM) is a solution for managing complex warehouse operations. It helps you track inventory, optimize space, and handle everything from receiving items to shipping.

With SAP EWM, you can:

Receive goods: Unload trucks, check the condition of items, perform deconsolidation or repacking if needed, and store them in the right place.Manage resources: Assign tasks to workers, equipment, or robots, and track how long they take to complete them.

Keep track of inventory: See exactly where each item is, how many you have, and whether they’re ready to use or ship.

Use space smartly: Store goods based on their size, how often they’re used, or any special storage needs.

Pick and pack: Choose items using different picking strategies, pack and label them, and get them ready for shipping.

Ship out: Load items onto the right trucks, print shipping labels, and send updates about delivery status.

The Material Flow System (MFS) is an advanced feature inside SAP EWM. It lets the software directly communicate with automated equipment like:

- Conveyor belts,

- Automated Storage and Retrieval Systems (ASRS),

- Shuttle systems,

- Sorters,

- Elevators,

- Robotic arms.

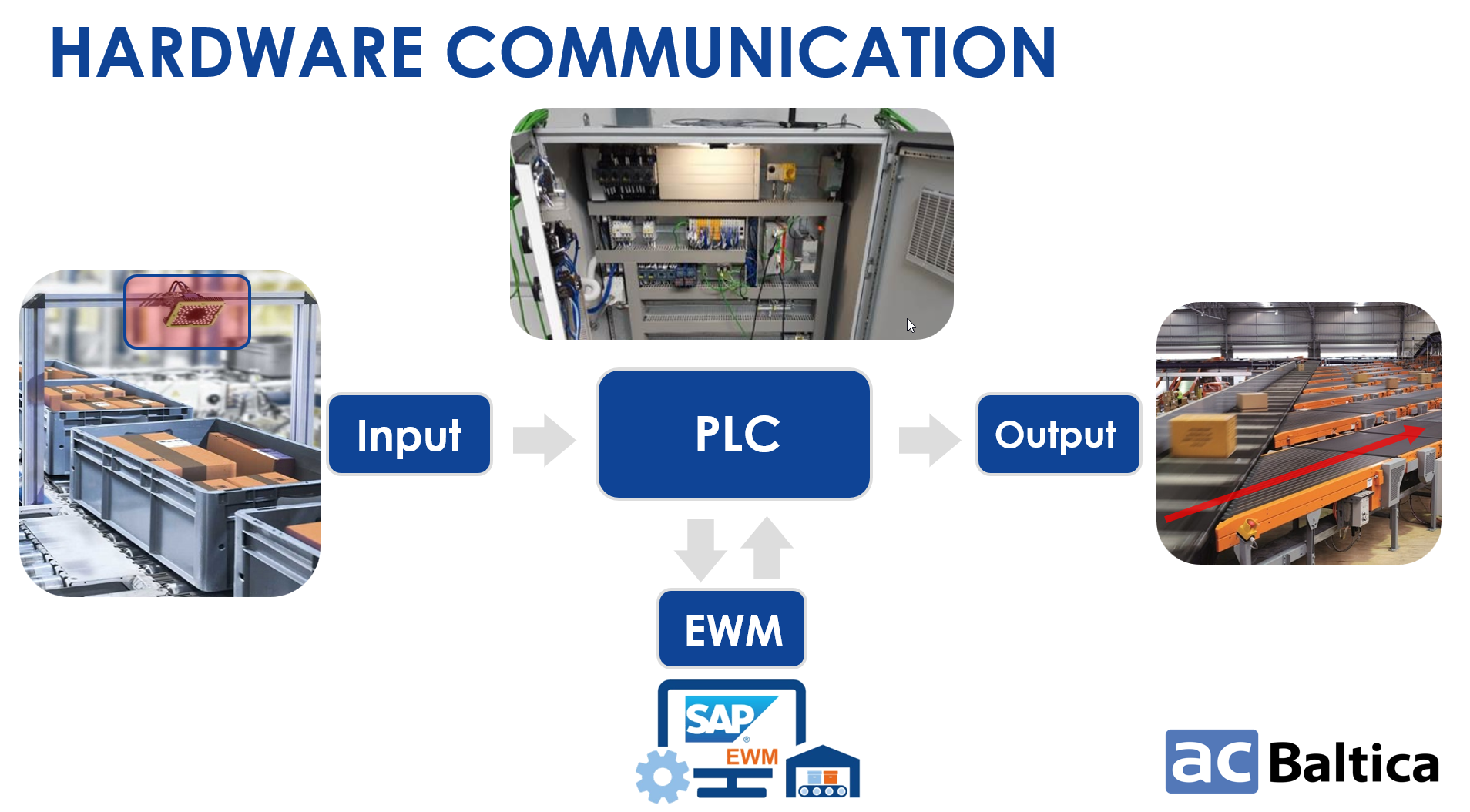

Usually, machines are managed by a separate system called a Warehouse Control System (WCS). But MFS lets SAP EWM talk directly to the machines via IP/TCP protocols and Programmable Logic Controllers (PLCs). These PLCs are like special computers inside the machines that understand and carry out commands.

For example, SAP EWM can tell a conveyor to move a pallet to high-bay storage. Or it can tell an elevator to transfer goods between floors. All of this happens automatically and in real time.

How SAP MFS works: Step-by-step process

Here’s a step-by-step look at how MFS operates inside your warehouse:

- SAP EWM sends instructions

SAP EWM creates telegrams — data packets with instructions like “Move this pallet to zone A.” These are sent over standard network protocols (like TCP/IP) to PLCs. SAP EWM stays in control of the whole process, while the PLCs pass the instructions to the machines and make them move, lift, or sort items as needed. - Equipment executes tasks

Next, machines receive a telegram and act according to the data received from the telegram, performing tasks automatically, without human intervention. For example, a sorter may direct fragile items to a special handling area, or a shuttle system may retrieve a specific box from storage. - Machines report back

When the task is completed, the machine sends a status update back to SAP EWM. This feedback confirms whether the task was successful or reports issues like delays, space shortage, or mechanical faults.

Such messages are empowered by built-in sensors and feedback loops that monitor equipment position, motion, and load in real time. - SAP EWM monitors in real time

With continuous updates from machines, SAP EWM keeps a live overview of the entire warehouse operation. It tracks every pallet, box, and machine status in real time. If any problems occur — like a stuck pallet or a jammed sorter, no space in the storage location, or a missing expected item — the system can trigger automatic corrections or alert warehouse operators.

When do you need MFS in SAP EWM?

MFS becomes essential if you have automated equipment in your warehouse. These systems operate at high speed and handle large volumes, and they need precise coordination and real-time communication. MFS allows SAP EWM to communicate directly with these machines, thereby eliminating the need for a separate warehouse control system (WCS). This means higher productivity, fewer integration points, and less error possibilities.

MFS is especially valuable in industries where time and efficiency matter most. For example:

- In e-commerce, where thousands of items must be sorted and shipped within hours.

- In retail distribution centers, where fast turnaround and accurate deliveries are important.

- In the automotive or pharmaceutical industry, where specialized handling and tracking capabilities are key.

- In the 3PL (third party logistics) industry, where flexibility and speed determine competitiveness.

- In production supply integration:

- Deep integration with SAP PP — EWM receives production order requirements, plans and assigns material release tasks

- Material withdrawal by Kanban signals — EWM connects to Kanban controllers or PLCs, generates restocking orders and manages the container movement.

Benefits of using MFS in SAP EWM

Reduced operational latency: By eliminating a separate WCS layer, MFS enables SAP EWM to dispatch commands directly to PLC-controlled equipment. The result is fewer integration points, lower software latency, and faster execution of tasks on conveyors, sorters, or other machinery.Fewer delays and mistakes: As machines communicate directly with SAP EWM and provide immediate reports, the chance of errors or delays is reduced.

No need for an extra control system: With MFS, you don’t need a separate system like a Warehouse Control System (WCS) to handle machine operations. This saves money and simplifies the setup.

Better use of equipment: MFS can help machines work smarter, not harder. It knows what equipment is free and efficiently assigns tasks to avoid bottlenecks.

Improved visibility: You always know what’s happening in the warehouse, where your goods are, and what machines are doing.

Reduced manual work: With MFS, machines handle repetitive tasks, freeing up your team to focus on more important work.

More reliability in peak times: MFS helps your warehouse stay efficient even during busy times like holidays or big sales.

Challenges and limitations of MFS

While MFS is a powerful tool, it's not always the right solution for every business. Here are some points to consider:

Equipment compatibility required: MFS relies on direct communication between SAP EWM and warehouse equipment through PLCs. If your equipment doesn’t support PLC-based integration, you may still need a Warehouse Control System (WCS) to handle communication.Complex integration: Connecting different machines from different vendors can be challenging and may require custom development.

Specialized knowledge needed: Integrating MFS and PLCs requires knowledge of both SAP and industrial automation.

Maintenance and monitoring: While MFS provides real-time monitoring through SAP EWM, effective operations may still require additional dashboards, alerts, or support tools — especially in high-volume or mission-critical environments.

Conclusion

MFS is an essential capability in SAP EWM that helps an automated warehouse run efficiently by allowing SAP to interact directly with the machines. This speeds up operations, improves accuracy and reduces the need for additional systems or manual intervention.

You should consider MFS if your warehouse uses automation, handles large volumes, and needs precise, real-time control over material movement. It’s especially valuable in industries like automotive, retail, pharmaceuticals, and logistics, where timing and efficiency matter most.

However, MFS comes with its own complexity and cost, so it’s important to evaluate whether it’s the right fit for your operations. If you’re not sure, it’s best to speak with our consultants who can help assess your needs and guide you toward the right solution.