Artem Latyshev, SAP EWM MM Consultant, ACBaltica

Imagine a production environment without integration between the warehouse and production planning: components don’t arrive on time, assembly lines stand idle, workers waste hours searching for parts, and finished goods pile up in storage. Costs rise, customer satisfaction drops, and chaos spreads.

Fortunately, there’s a solution. SAP Extended Warehouse Management (EWM), tightly integrated with Production Planning (PP), synchronizes material movements with production orders, tracks consumption precisely, and gives full control over warehouse and production flows in real time.

What is SAP EWM?

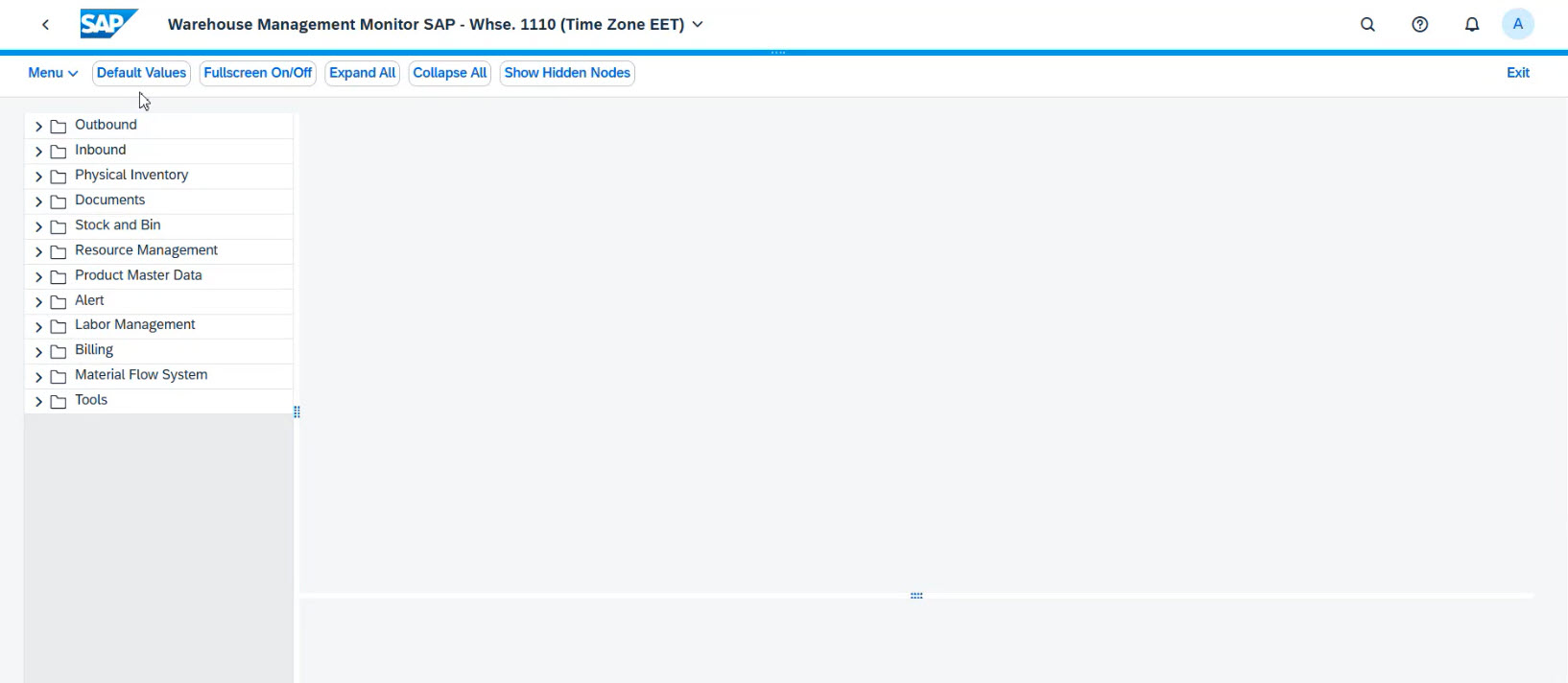

SAP Extended Warehouse Management (EWM) is a central system that controls and optimizes all warehouse operations. It manages inbound and outbound logistics, storage, picking, packing, labor, and quality control. The system tracks every movement in real time, showing where materials go and which resources handle them.

But EWM goes far beyond classic warehouse management. Its strength lies in how it integrates with other SAP modules to orchestrate end-to-end supply chain processes.

What is SAP Production Planning (PP)?

SAP Production Planning (PP) is one of the core ERP modules that organizes and controls manufacturing processes. It defines what should be produced, when, in what quantity, and with which resources. At the heart of PP lies the production order, which contains critical information about the finished product, its required components, the necessary operations, and the relevant dates. The production order initiates and drives the production process in the system.

How SAP EWM and SAP PP work together

Here is the core process:

-

Requirement from PP – Production Planning sends requirements to EWM, specifying which parts production needs and when.

-

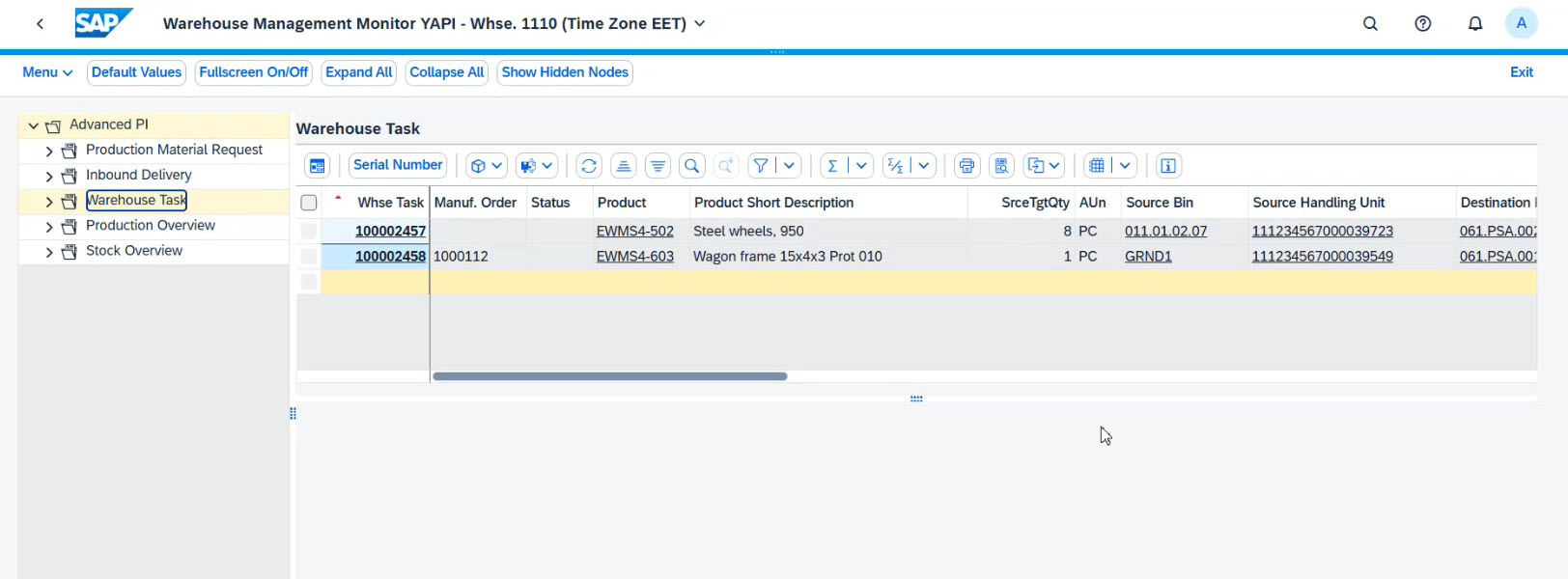

Warehouse tasks created – EWM automatically generates warehouse tasks.

-

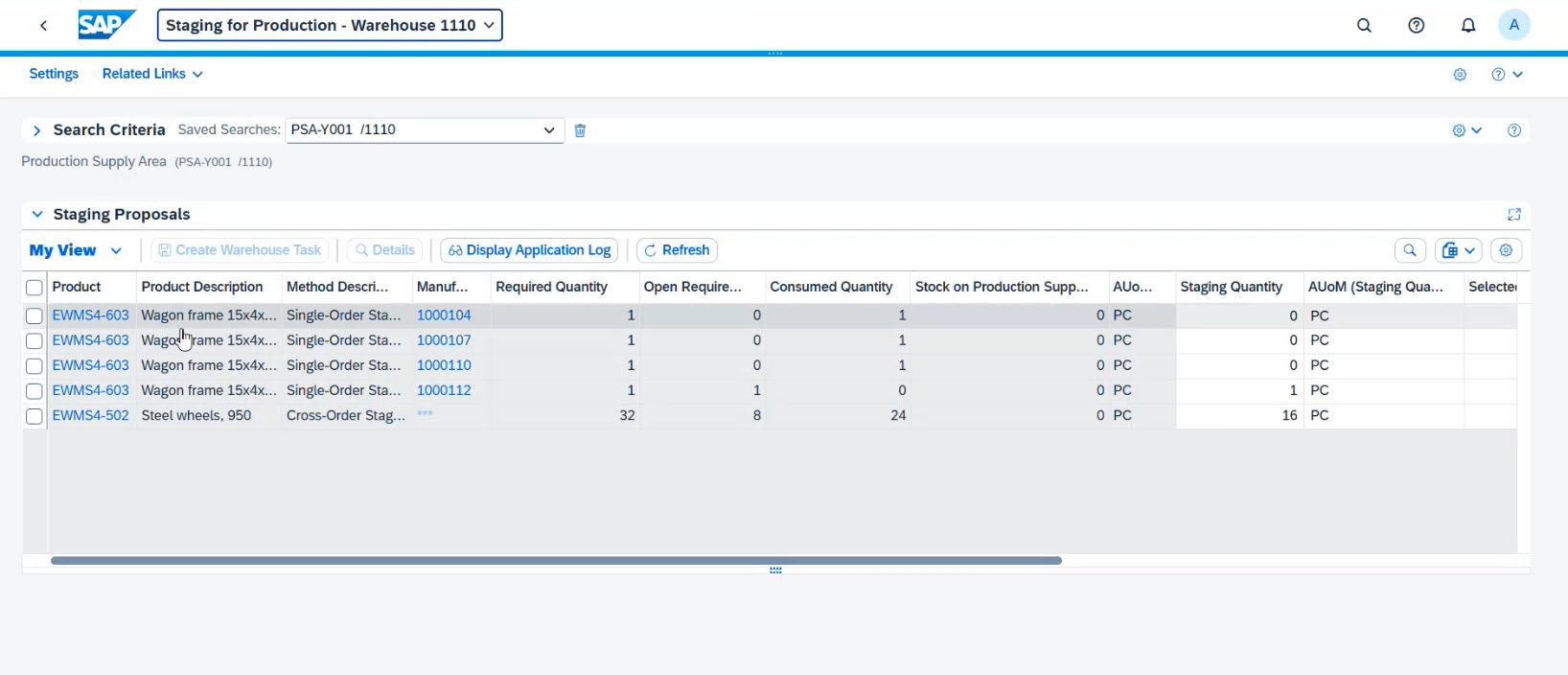

Staging in PSA – Warehouse staff collect materials from general storage and transfer them to the Production Supply Area (PSA). The PSA is a dedicated area where workers keep production-ready parts before sending them to the line.

-

Consumption in production – When workers move parts from the PSA to the production line, consumption starts.

-

Return flow – Once production consumes components and finishes the assembly, the finished goods return to the warehouse for storage and further processing.

When SAP EWM and SAP PP work together, the warehouse always knows what the production team needs and when. Materials arrive at the right place on time, production doesn’t have to stop and wait, and everyone sees the same up-to-date information about stock and orders.

SAP EWM and SAP PP integration models

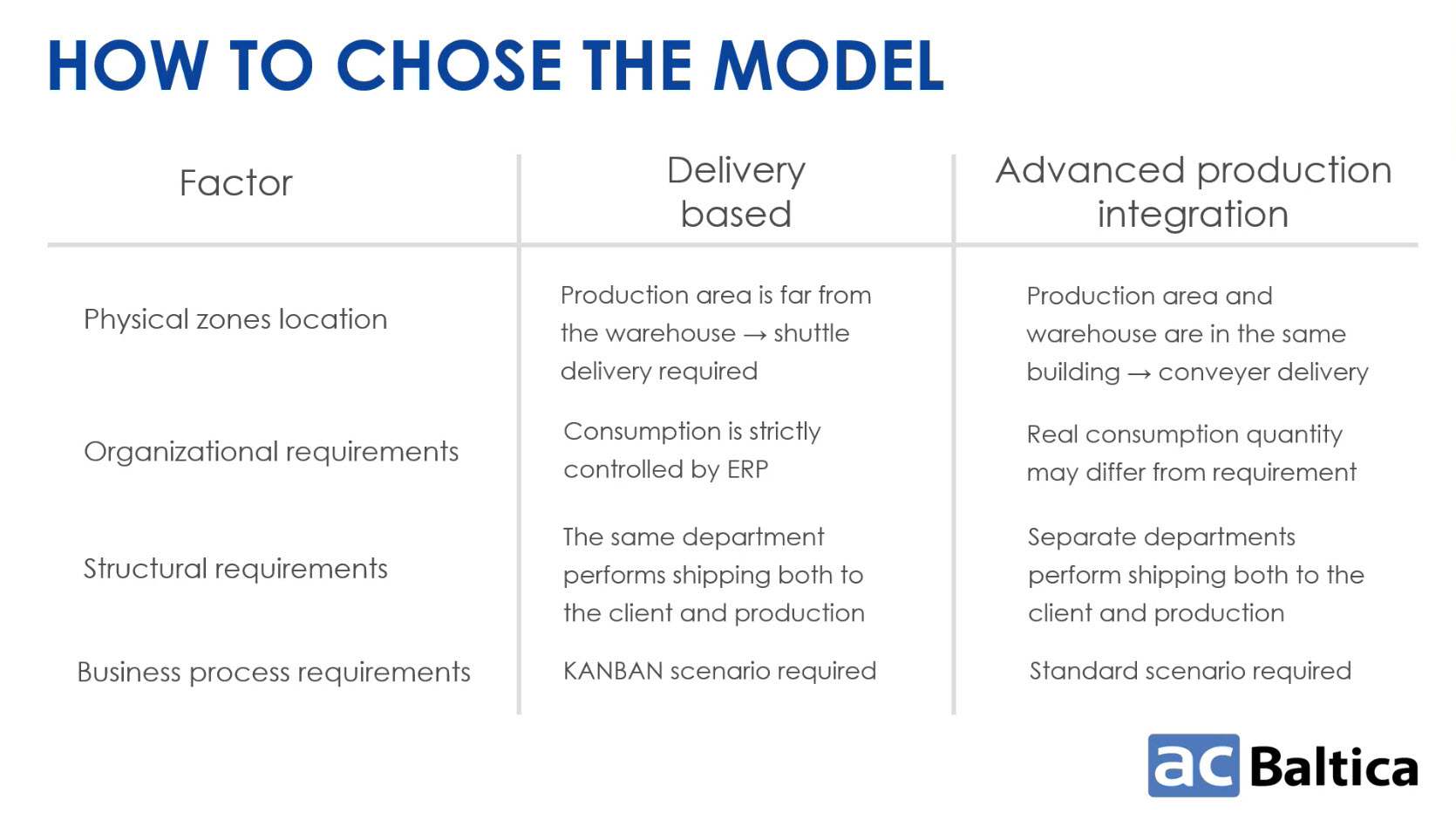

There are two standard integration models:

Delivery-Based Integration

- PP generates delivery documents for required materials.

- EWM uses them to execute staging and consumption.

- Best for stable, delivery-driven operations.

Advanced Production Integration

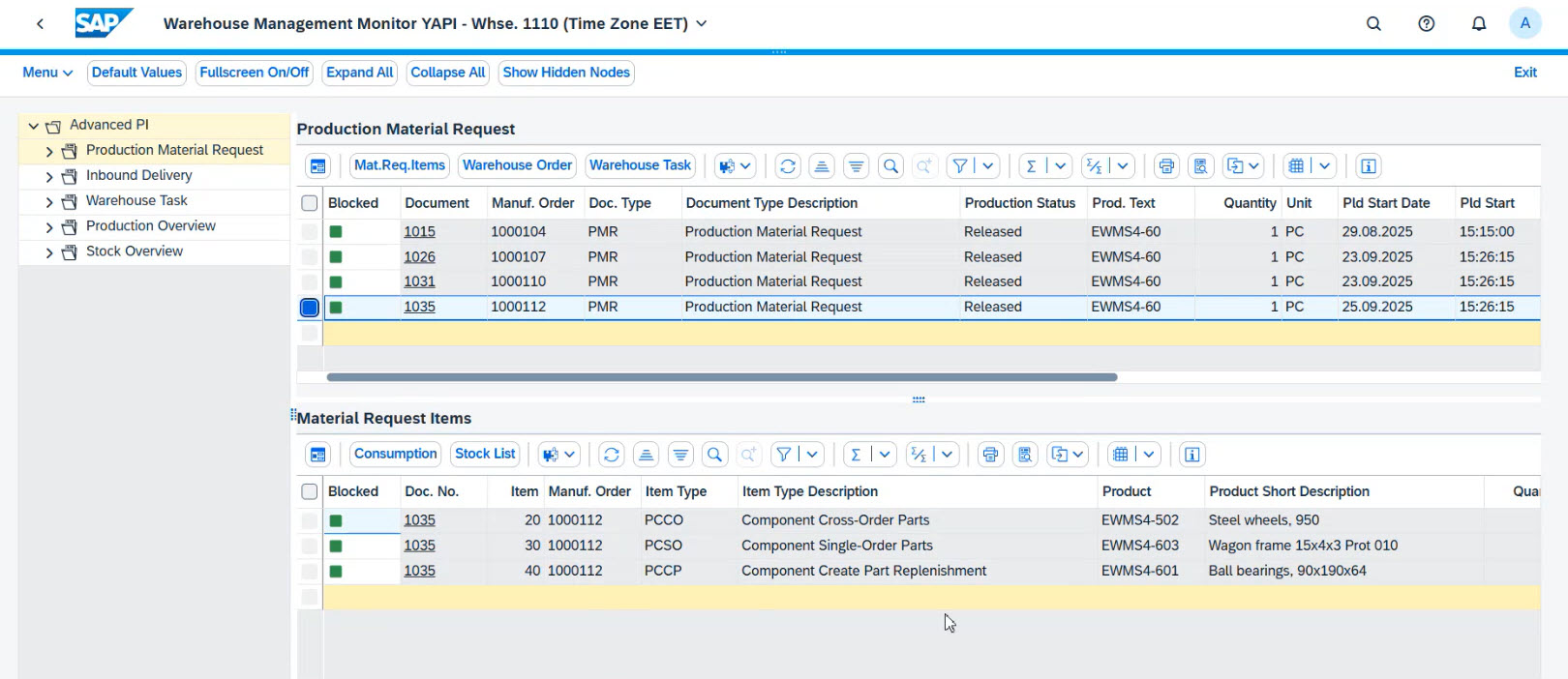

- PP creates Production Material Requests (PMR), which are replicated into EWM.

- EWM manages staging, consumption, reversals, and reporting directly.

- Best for dynamic and flexible manufacturing environments.

How to choose the right SAP EWM–PP integration model

Core integration objects

- Production Order – The starting point of the chain. It specifies what to make, which components are needed, and when. It also includes the work center number, which maps to a Production Supply Area (PSA).

- Production Material Request (PMR) – In the Advanced Production Integration model, EWM receives production order information as a Production Material Request (PMR). This document gives warehouse managers everything they need to plan work, start staging materials, and manage the process.

Example: Wagon assembly

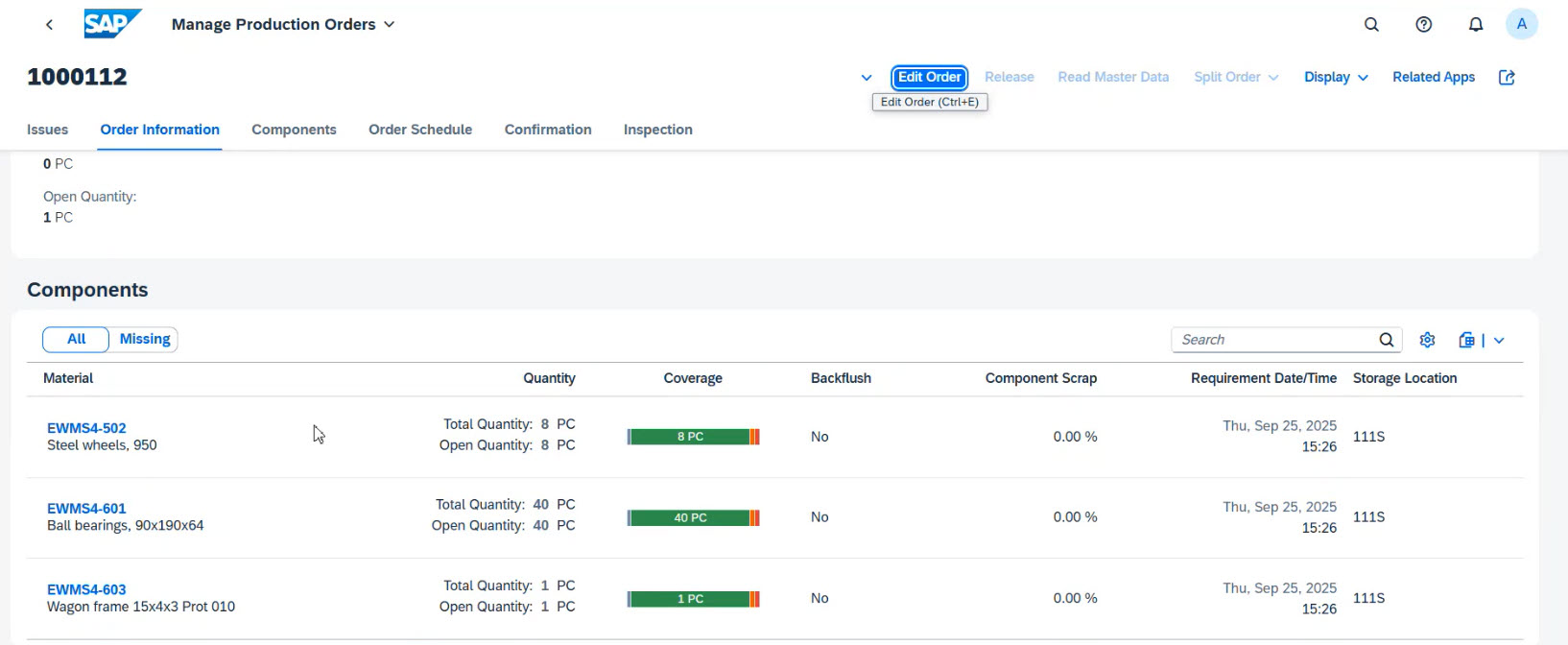

Production Order components

A PMR groups production components into four categories. Each category follows its own staging strategy, helping warehouse staff understand how to pick, stage, and restock every part:- Pick parts: Unique to a specific order, staged directly to PSA (e.g., wagon frame).

- Cross parts: Shared across multiple orders, efficiently managed across PSAs (e.g., wagon wheels).

- Non relevant for staging parts: materials not staged through EWM (e.g., bulk materials).

- Crate parts: Continuously consumed materials, replenished automatically to maintain minimum stock levels (e.g., ball bearings).

The process we describe here is divided into three key roles:

- Production Planning

- Warehouse

- Warehouse Picker

Production Planning view

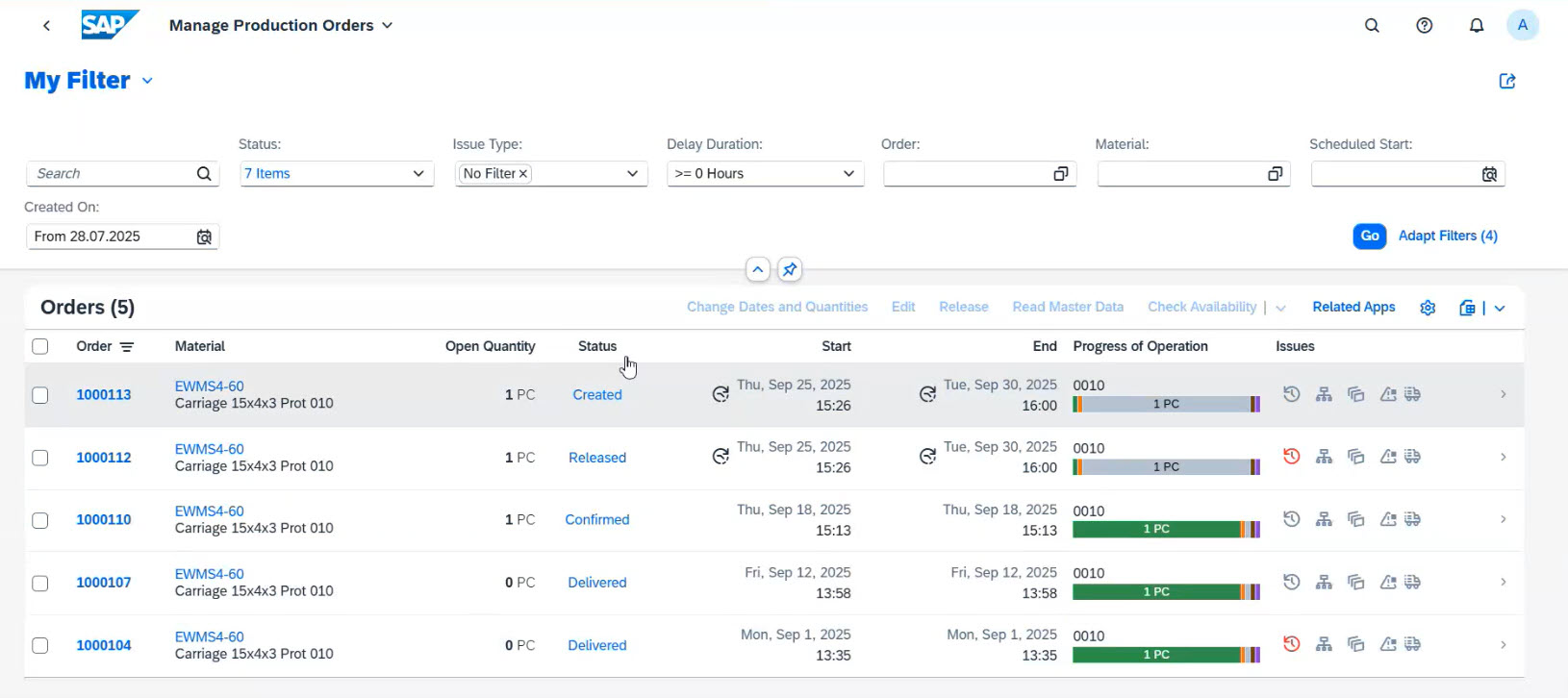

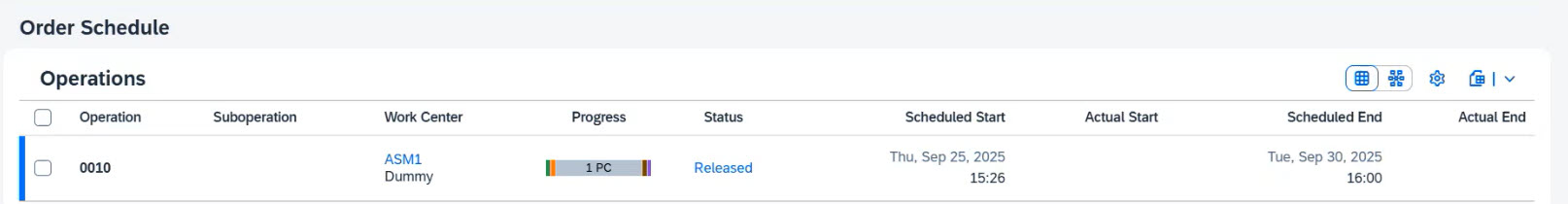

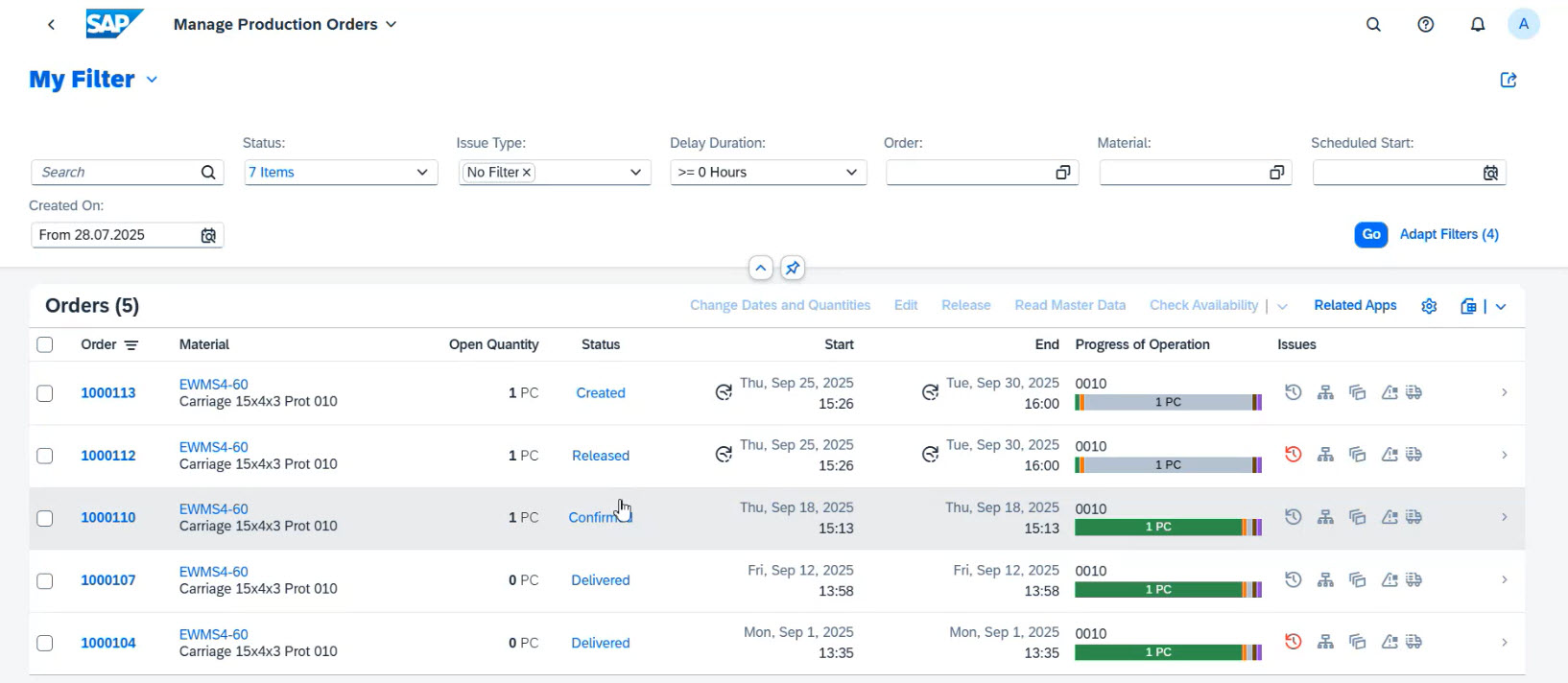

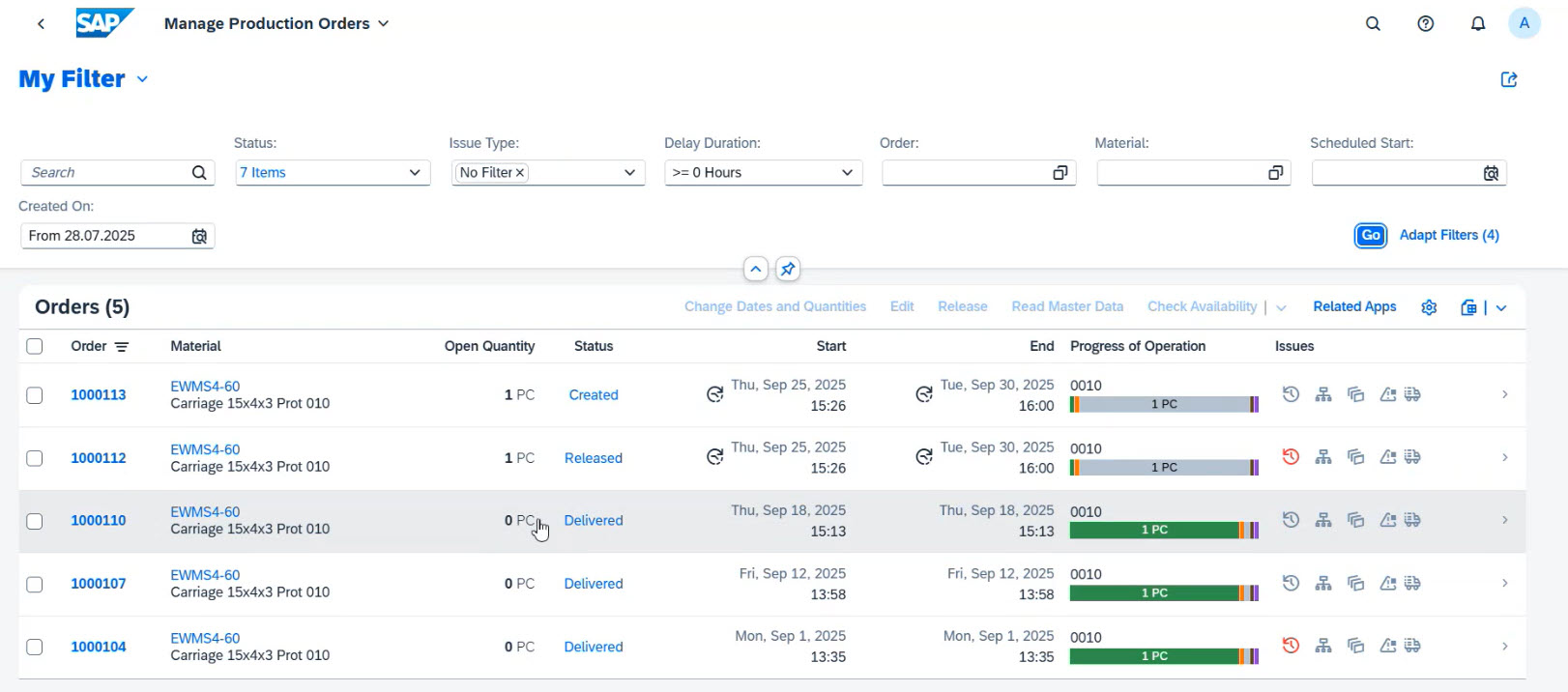

Manage Production Order report

- Delivered means the product is already in the warehouse.

- Confirmed indicates assembly is complete and the goods are ready for receipt.

- Released shows that components are available for staging and can be processed in the warehouse.

- Created means the order exists but is not yet ready for warehouse handling.

Order information

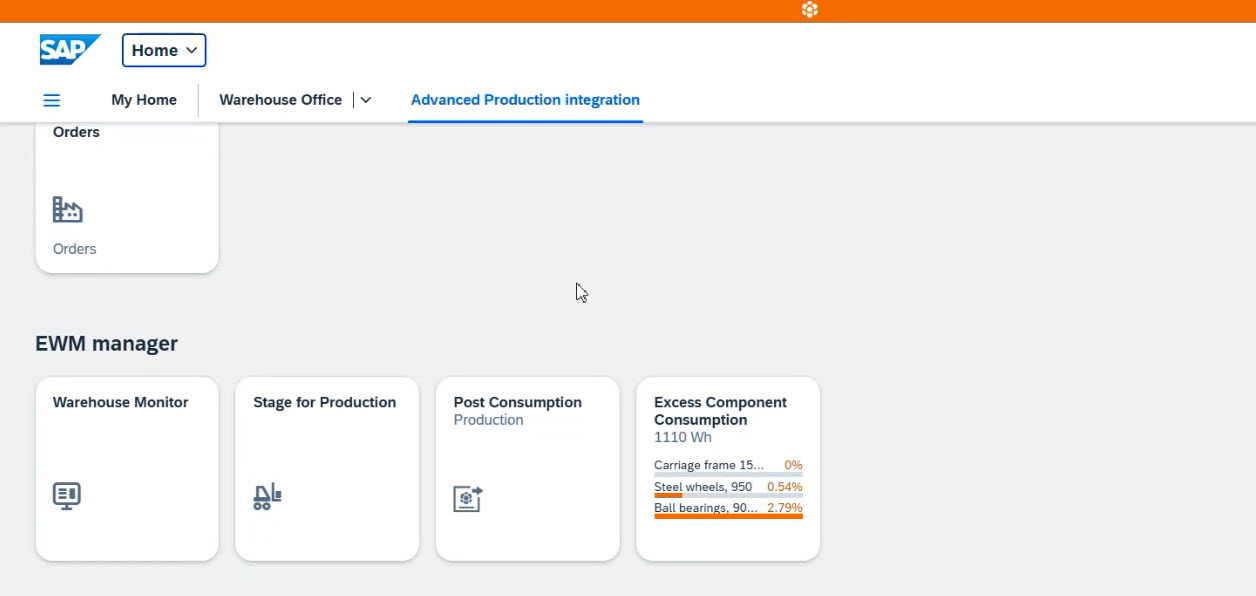

Warehouse view

Stage for Production

Staging starts by entering the required quantities and selecting the relevant lines, which generates warehouse tasks automatically, while the system chooses the best storage bins for picking based on warehouse, access types, and process configurations.

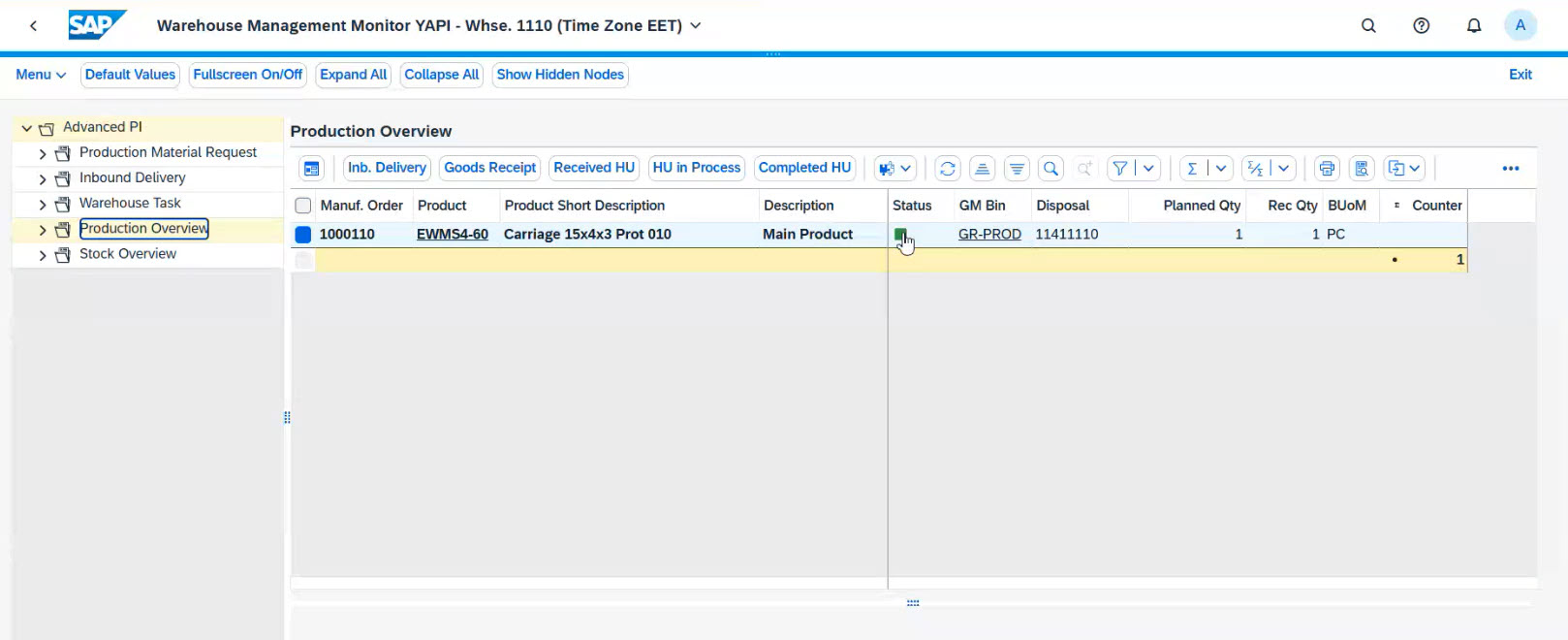

Warehouse Management Monitor

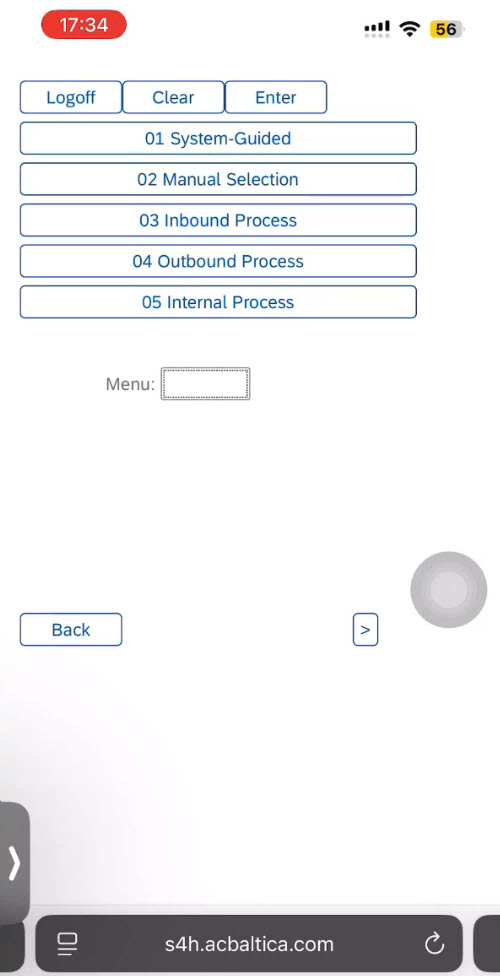

In practice, warehouse tasks are typically confirmed by stockkeepers using PDA devices. However, SAP also allows managers to confirm tasks directly from the Warehouse Management Monitor. Once a task is confirmed, it disappears from the open tasks list, keeping the view up to date.

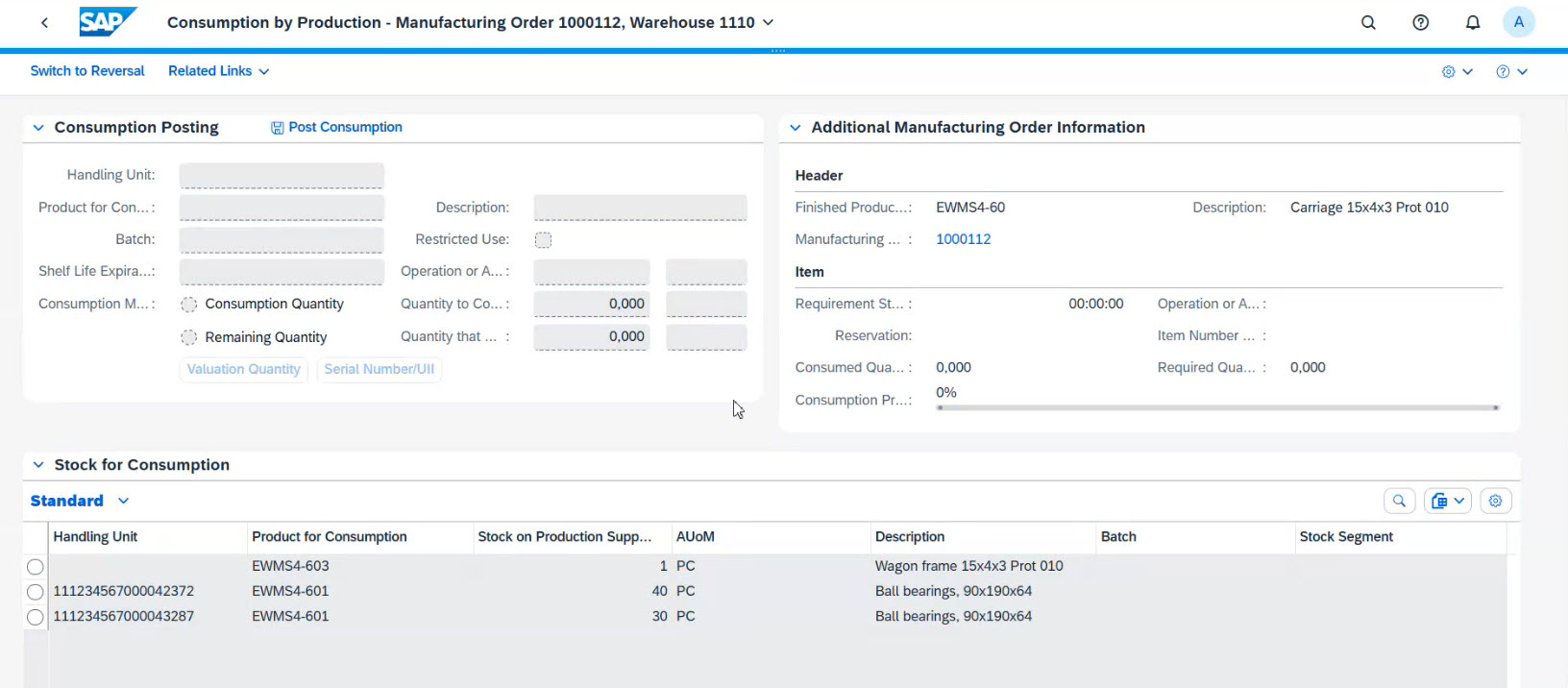

Consumption

The post consumption process is managed through a dedicated tile. This allows warehouse staff in the Production Supply Area (PSA) to issue components to the production line and record their usage in the system.

The Advanced Production Integration model supports flexible consumption, allowing warehouse staff to issue quantities exceeding the original plan if necessary. This ensures that additional needs (like extra ball bearings) can be accommodated without disrupting the workflow.

Once consumption is posted, the Managed Production Order report reflects the updated status and quantities, providing a clear overview of what has been issued versus what remains to be consumed.

Reversal

Over-consumption

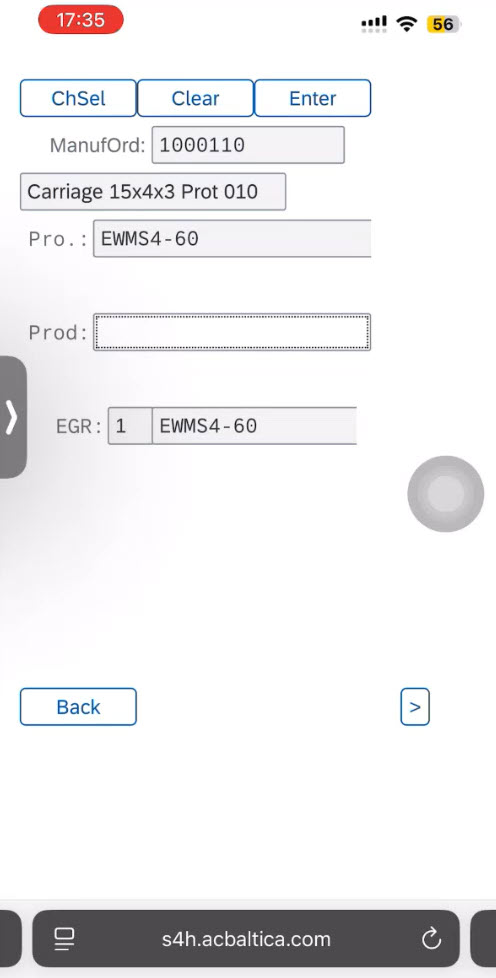

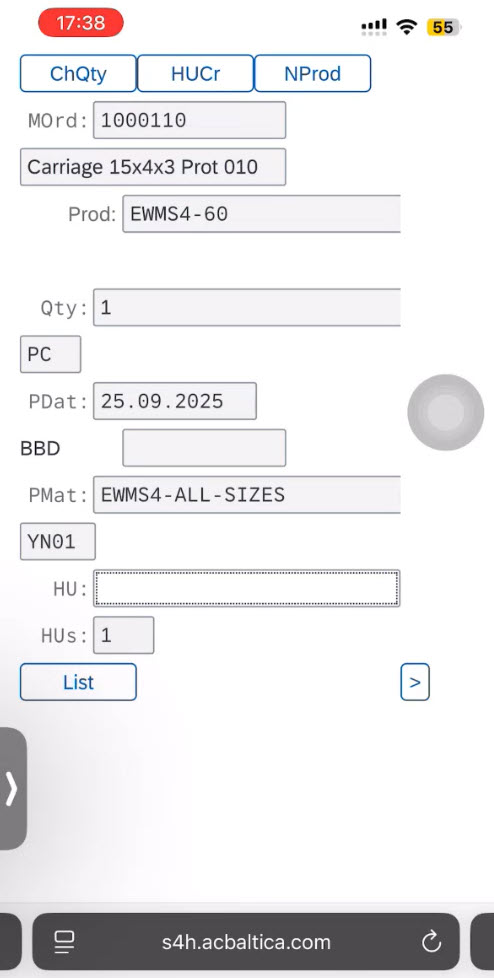

Good receipt: mobile view

Together, the Status Report and the Production Overview Report confirm that the finished product has been successfully received and stored in the warehouse.

Key business benefits of integrating SAP EWM with SAP PP

SAP EWM links warehouse operations with production planning so the warehouse can directly support and stay in sync with manufacturing. Its key advantages include:

-

Improved efficiency – automated goods receipt and putaway tasks reduce manual work and speed up warehouse-to-production processes.

-

Greater flexibility – staging and consumption can adapt to actual production needs, ensuring smoother operations even in changing conditions.

-

Better inventory visibility – synchronized material flows provide real-time insights into stock levels, helping avoid shortages and overstock.

-

Optimized space utilization – flexible staging planning for production supply areas (PSAs) ensures warehouse and production areas are used effectively.

-

Reduced errors and rework – simple reversal processes and clear documentation minimize mistakes in handling and reporting.

-

Mobility and accessibility – desktop and mobile interfaces empower both warehouse and production staff with easy-to-use tools.

About the author