Artem Latyshev, SAP EWM MM Consultant, ACBaltica

Handling serial numbers in SAP Extended Warehouse Management (EWM) can be a challenge — especially when business requirements don’t align with SAP’s standard process flow. In this post, we’ll walk through a real-world customer project where we customized the goods receipt (GR) process to meet specific needs, focusing on serial number handling. We'll explain the key decisions, challenges, and how different serial number requirements (‘B’, ‘C’, and ‘D’) played a role.

The challenge: making goods receipt easy and flexible

In any warehouse project, one of the biggest challenges is bridging the gap between SAP's standard processes and how people actually work on the ground. Many warehouse employees aren’t SAP experts, and using unfamiliar or complex transactions can slow down their work.

That was exactly the situation we faced in this project. Our customer asked us to design a goods receipt (GR) process that met the following key goals:

- Simple and fast for warehouse users, especially those working on laptops and PDAs.

- All items had to be received at once, using a single document, right when the truck arrives, and goods are unloaded into the acceptance area.

- Serial numbers and expiration dates couldn’t be entered until later — sometimes days later — when the items were unpacked.

- Users should be able to maintain expiration dates and serial numbers during packaging (when creating handling units), not during the initial GR step.

However, the standard SAP EWM PDA app, Receiving Handling Units by Delivery/ASN, didn’t support this. In that app, GR is posted only when a handling unit (HU) is created — but our customer needed to post the GR before HU creation.

To solve this, we designed a custom logical transaction for PDA use. Our goals were:

Reduce complexity: Fewer button clicks, clear navigation, and only essential data input.Make expiration date entry possible at the right moment (during HU packaging).

Provide a consistent, user-friendly experience tailored to warehouse operations.

This custom solution made the acceptance process much more efficient. But there was still a key challenge left: how to handle serial number entry when the GR had already been posted.

That’s where we turned to Harmonized Serial Number Profiles and Provisional Serial Numbers.

Inputting serial numbers after GR posting

Since the customer was using a recent version of S/4HANA and had activated Enable Harmonized Serialization in EWM, we used Harmonized Serial Number Profiles to manage serial numbers.

For more information, see: https://help.sap.com/docs/SAP_S4HANA_ON-PREMISE/9832125c23154a179bfa1784cdc9577a/49cacb53ad377114e10000000a174cb4.html

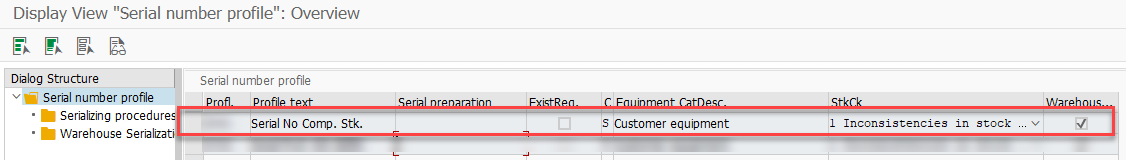

SPRO - SCM Extended Warehouse Management - EWM - Master Data - Product - Serial Number Profiles - Harmonized Serial Number Profiles - Define Serial Number Profiles

To allow entering serial numbers after the GR was posted, we used the Provisional Serial Number feature.

For more information, see: https://help.sap.com/docs/SAP_S4HANA_ON-PREMISE/9832125c23154a179bfa1784cdc9577a/e9c8cb53ad377114e10000000a174cb4.html

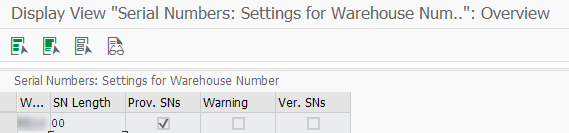

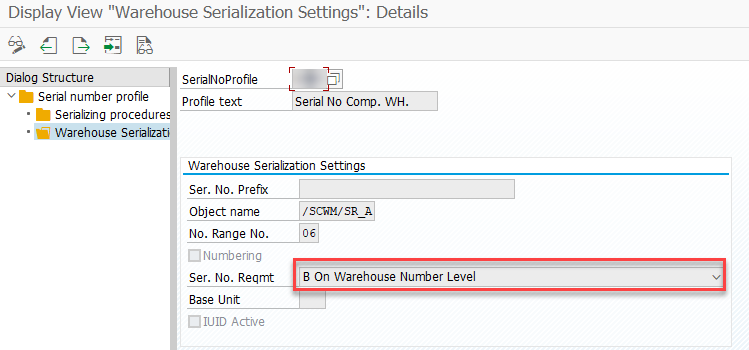

SPRO - SCM Extended Warehouse Management - EWM - Master Data - Product - Serial Number Profiles - Serial Numbers: Settings for Warehouse Number

With the right settings:

- The system generates temporary serial numbers (starting with $) during GR.

- These serials are stored in the table /SCWM/SERI.

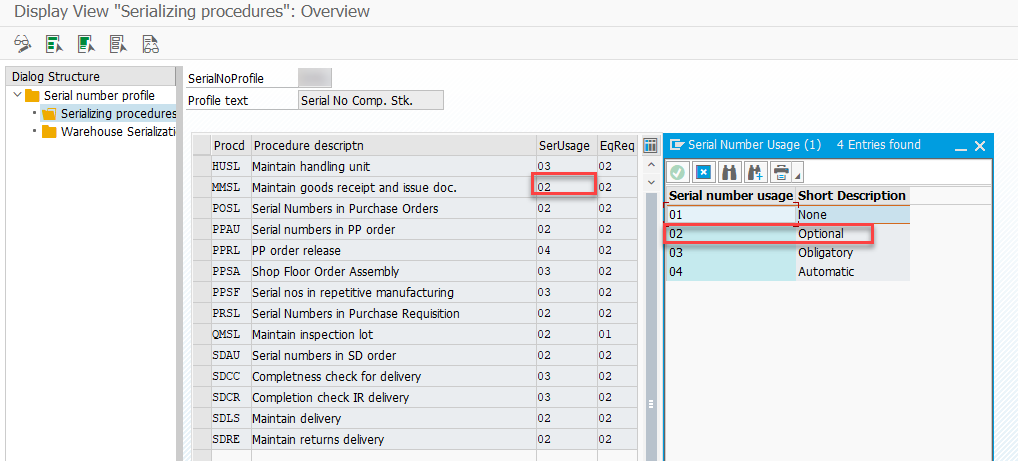

- To avoid errors in queue SMQ2, we had to set serial number usage to Optional for the MMSL procedure.

SPRO - SCM Extended Warehouse Management - EWM - Master Data - Product - Serial Number Profiles - Harmonized Serial Number Profiles - Define Serial Number Profiles - Serializing procedures

Note: Serialization must be active for the inbound delivery item type, and you should follow SAP Note 2956967 for setup.

Choosing the right serial number requirement: ‘B’ or ‘C’?

We then had to decide which Serial Number Requirement type to use:

‘B’ – Serial Numbers at Warehouse Number Level: Easy for users — they only need to enter serial numbers during receiving or issuing.‘C’ – Serial Numbers in Inventory Management: More control — you can track each serial number in the warehouse and see exactly where it is.

Our customer used requirement ‘C’ in other warehouses, but we considered ‘B’ for simplicity in the new setup.

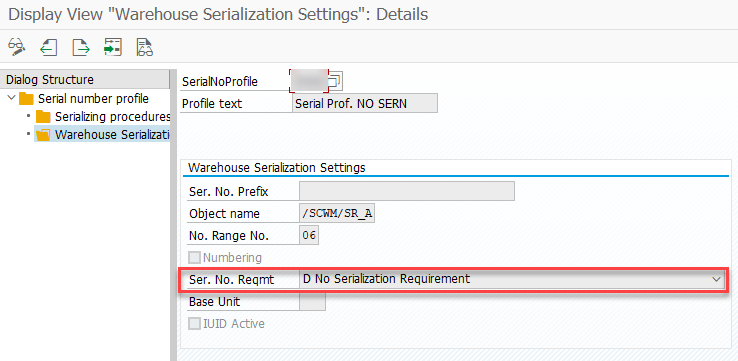

SPRO - SCM Extended Warehouse Management - EWM - Master Data - Product - Serial Number Profiles - Harmonized Serial Number Profiles - Define Serial Number Profiles - Warehouse Serialization

However, testing showed that:

- Label printing forms didn’t work with ‘B’, making integration harder.

- Fixing incorrect serial numbers was trickier and not supported by standard corrections like the ones in SAP Note 3466332 (Changing serial numbers using Physical Inventory Process).

In the end, we decided to go with requirement ‘C’, refining the custom PDA transaction accordingly.

What about requirement ‘D’? When it's useful

One last challenge in the project had to do with transferring stock between two warehouses that belonged to different plants — let’s call them:

Plant A – the supplying (or buffer) warehouse, where materials are first received.Plant B – the receiving (or main) warehouse, where materials are unpacked and serial numbers are recorded.

The business process looked like this:

-

Goods arrive from an external supplier and are delivered to Plant A.

-

At Plant A, warehouse staff accept and store the materials, without entering serial numbers (because they aren’t available yet).

-

Later, materials are transferred to Plant B using a Stock Transfer Order (STO).

-

At Plant B, during unpacking, staff enter the correct serial numbers.

The logical solution?

In Plant A’s material master, no serial number profile would be used (so serial numbers aren’t required). In Plant B’s material master, a serial number profile with requirement ‘C’ (Serial Numbers in Inventory Management) would be used to enforce entry during processing.

However, SAP standard behavior blocks this setup by default. According to SAP Note 1519543, SAP doesn’t allow different serial number profiles for issuing and receiving plants in an STO process. This is to prevent data inconsistencies for materials and serial numbers.

The Solution: Serial Number Requirement 'D'

Luckily, SAP Note 3536808 describes an approach that makes this scenario possible.

With a combination of:

-

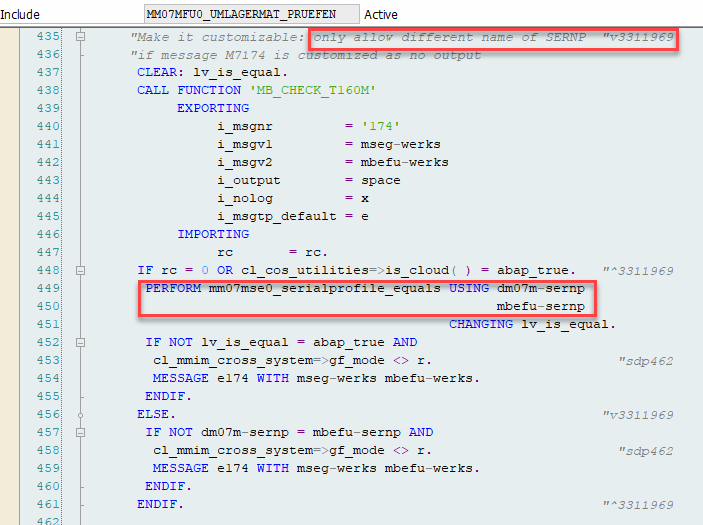

SAP Note 3311969 (which adjusts how the system handles serial number profiles in STOs),

-

A message suppression in transaction OMCQ (for message M7 174),

-

And a careful look at the backend logic,

... it's possible to assign different serial number profiles in different plants, as long as the serializing procedures are identical inside both profiles.

Include MM07MFU0_UMLAGERMAT_PRUEFEN, changes according to the SAP note 3311969

Note: When Requirement 'D' was introduced, detailed guidance and examples were quite limited. At the time, SAP’s documentation offered only a brief description in the configuration help:

“You use this serialization requirement so that you can record serial numbers in certain processes or revoke the serialization requirement in a certain warehouse number.”

This left many questions open, especially the difference between using Requirement 'D' and not assigning a serial number profile at all. In our case, we essentially had to invent and validate a working example where 'D' made sense and solved a real business need.

Here’s what we did:

-

Created a new serial number profile for Plant A, using requirement 'D' – No Serialization Requirement.

-

Kept the same serializing procedures as the profile used in Plant B.

-

Linked this requirement 'D' profile to materials in Plant A.

Why Requirement 'D' Works

With requirement 'D':

-

Plant A doesn’t require serial number entry during Goods Receipt or internal movements.

-

But Plant B still enforces serial number entry, so data consistency and traceability are maintained.

This approach allowed the customer to keep their buffer-stock process clean and simple at the supplying warehouse, while ensuring proper tracking and control at the main warehouse.

Conclusion

This project shows how SAP EWM can be adapted to fit real-life warehouse processes — even when they don’t align perfectly with SAP’s standard approach.

If you are facing similar challenges in serialization or receiving goods using EWM, the key is to deeply understand SAP's capabilities and know when to back off (safely) to meet real business needs.

Whether you're creating a new warehouse or streamlining existing processes, our consultants can help you create serialization workflows that work for your team, not against it.